“Congratulations,” the email started, “you have been selected to attend our first Lockheed Martin Tweetup”. That led to frantic trip planning, and a bunch of excitement.

Twitter and these ‘Tweetups’ have given me an incredible number of experiences that most could never imagine, something I’m very thankful for. My first Space Shuttle launch at STS-129, visiting Mission Control for STS-130 (forever cementing my human space flight geekiness) technically our entry with @MyTransponder to the Boeing DreamLiner before the public were admitted at Oshkosh, and now this.

This? Being present for the factory rollout of the final F/22 Raptor, SN 195 and an opportunity to spend some time in one of the simulators (later learning it’s technically the “cockpit demonstrator.” While it is a real chunk of airframe with accurate controls, the things displayed on the screen and HUD are the unclassified version.) Oh, and we’ll be going through the C-130J and P-3 wing assembly lines. And I was one out of the 14 selected of 60 applicants.

We arrived and were escorted to B(uilding) 2 on Dobbins Air Force Base which connects to B-1, the building which holds the assembly lines for the C-130J, P-3 and (now being decommissioned) the F-22. There was mention of assemblies for the F-35 too, but we avoided those areas due to ITAR (International Traffic in Arms Regulations) concerns. Sound like a big building? Try 3.3 million square feet. To access our conference room, we had to walk into the factory area – and it was overwhelming. The sights, sounds and smell was very industrial – sort of like your local maintenance shop, only immaculately clean, tape on the floor indicating where each creeper, parts bin and tool box was to be kept when not required for some piece of assembly.

B-1 was built in a bit over a year to facilitate assembly of B-29s, and has been used for aircraft production most of the time since. It’s common to see anything from a small bicycle (with large baskets for carrying items) to full size pickup trucks driving in the aisles, which are the size of a normal two-way city street.

After introductions and discussing some of the rules (like no photography, period) we headed out through the factory floor, and inside the fenced-in-inside-the-building area where the Raptor was assembled – now empty, except for a single complete airframe, off the line and lit with spotlights. I incorrectly tweeted it looked baby blue – it did, but that was more due to the color the lights were programmed for. When it got outside it was definitely green, lighter so than you would see on a Boeing airliner, for instance, if you’ve watched their rollout festivities. A couple people spoke, a video was shown, and it was showtime. From our spot there’s a gigantic US flag under which is written “Through these doors pass the most awesome fighters in the world.” Some ways away more sobering statement can be found: “A mistake covered up may cost the life of a brave pilot.”

A loud bell began ringing (a safety indication that the hangar doors would be opening very soon) and a drumroll started. A local high school marching band would be following the plane. And the parade was off! The tug was pulling the airframe, followed by the marching band, the program and military leadership, and the employees. We were mixed into the employee group, the fourteen “tweeters” and our four “chaperones” who later said “it was easy to keep track of you all – we just had to look for who were looking down regularly and holding a smartphone”.

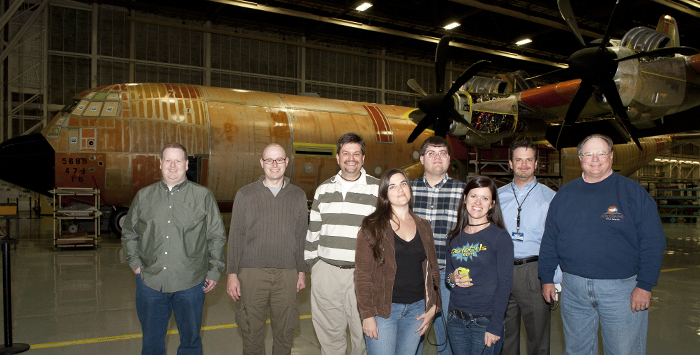

The convoy continued for some ways around the corner of the building and to the front, stopping at the intersection the Raptor would be taken down to be completed – testing the fuel tanks, final electronics work, and test flying before ultimately getting its paint and special stealth coatings and delivery in the summer of 2012. There the management, employee, marching band, and eventually we got our photos taken with the aircraft.

Everybody went back to work, and we headed back to our conference room for lunch. There two test pilots, Trigger (who of course would not explain his call sign) and JB (who wouldn’t even acknowledge HAVING a call sign) told stories and answered questions about their experiences doing production test flying on the Raptor.

After lunch came a split into two groups, and my group went out onto the C-130 and P-3 floor. Walking from station to station we saw a floor become an airframe, wings appear, and engines / propellers be installed until the very last spot where a completed Hercules awaited its trip to the paint booth.

Then it was time for fun – on to the cockpit demonstrator. It’s not full-motion, and the avionics displays aren’t the same since many capabilities are classified – but it’s a “legit” airframe and controls. We didn’t have much time, so we cycled in and out through air to air, air to ground and landing sorties – but the systems (at least what we could see) are incredibly advanced and pretty awe-inspiring.

If you came here expecting an objective view of the F-22 program, plane, or policy – sorry, this isn’t it. I’m a fanboy, and I will admit that without hesitation. This is an incredible aircraft with the technology to keep our pilots safe and enemies fearful. I’m thankful for the opportunity to visit and Lockheed Martin’s hospitality during our visit. Our entire group didn’t open a door during our entire visit – there was always someone there. It felt like we were actually somebody important. What a great trip!